Sustainability

From seed to suds: The journey of a sustainable, tech-traceable beer | TELUS

Sep 23, 2021

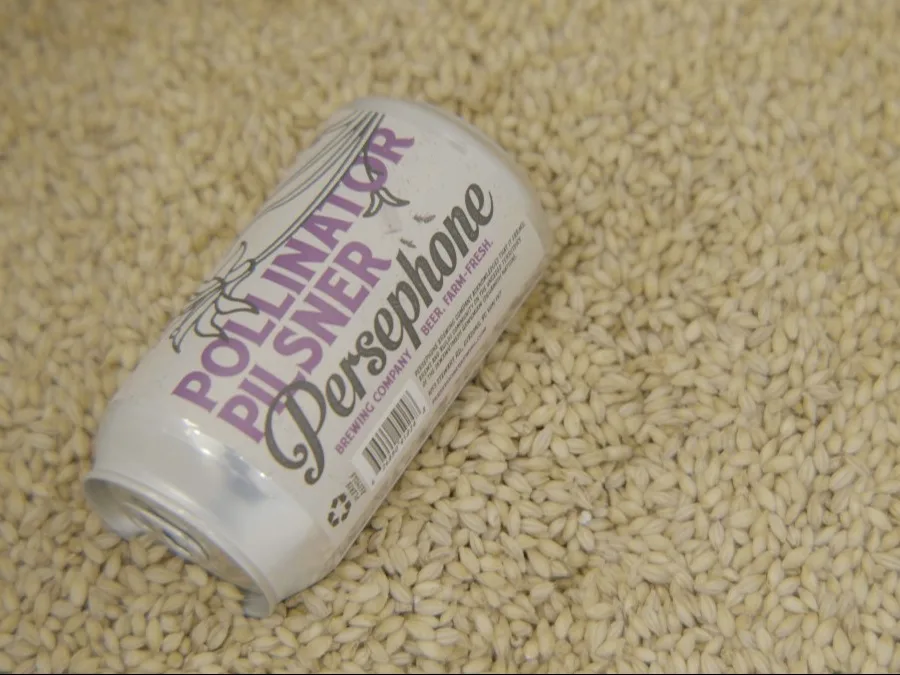

Beer begins with a few simple ingredients: water, yeast, hops, and malt. What makes each beer unique is how those ingredients are combined, grown, and flavoured. Enter the Pollinator Pilsner. Created by Persephone Brewing Company, the Pollinator Pilsner’s distinctiveness comes not only from its sustainably-grown ingredients but from its traceable production, powered by TELUS Agriculture.

Persephone and its farming partners worked with TELUS Agriculture to ensure that the barley used in the Pollinator Pilsner is sustainably produced and traceable from the planting of the seed, to harvesting, right through to the malting and brewing process. Integrating TELUS Agriculture technology, including

Decisive Farming

‘s precision agronomy and farm management tools and Muddy Boots

’ farm-to-food traceability, quality and supply chain management solutions, enables Persephone to give beer fans a complete, verified view of production. By scanning a QR code on the beer can, consumers can see the 1,200 kilometre journey from farm to brewery, learning how the Pollinator Pilsner is sustainably farmed, brewed, and monitored for quality and safety.Strong digital policy is missing from Canada’s climate strategy, and presents an opportunity to lead on global climate action.

“Partnering with Persephone is a clear example of how integrating agriculture technology through the value chain can complement and further sustainable commitments by integrating simple and supportive solutions,” said Nish Majarian, Interim President, TELUS Agriculture and Global Managing Director, Agribusiness.

Brian Smith, CEO and owner of Persephone, Canada’s only farm-based Certified B-Corp brewery, added, “Sustainability is a core driver for us in everything we do and we know it’s important to our customers too so we’re thrilled to be able to provide them with verified traceability.”

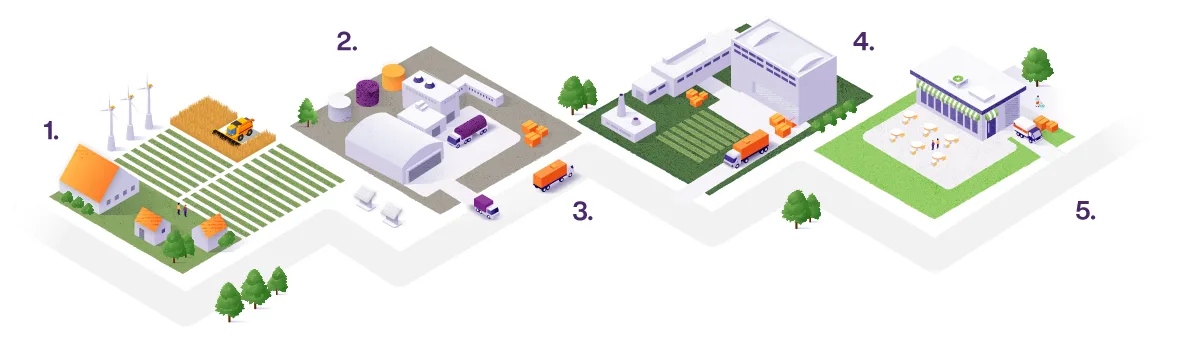

The sustainable and traceable path of the Pollinator Pilsner

- Farm

The journey starts on farm where barley seeds are planted, fertilized, sprayed and harvested using precision insights fromTELUS Agriculture Weather Stations, satellite imaging and Decisive Farming soil analysis and traceability solutions. This data-driven approach helps get the most from the land with the least environmental impact. - Processor

The harvested barley is then sent to Persephone’s processor to convert into malt. Using Muddy Boots quality management solution, the malt is checked for standards like moisture levels, weight and plumpness to ensure optimal quality. - Transport

The processed malt is packaged for shipment and monitored using Muddy Boots’ supplier management software. This solution verifies supplier standards are met and can pinpoint any issues down to the batch, enabling better food traceability and safety. - Brewery

At Persephone, the malt is brewed with local honey, water, yeast and hops, and monitored for quality and taste, backed by Muddy Boots’ quality management solution. - Consumer

The packaged pilsner is shipped to stores, with customers having the option of tracing its journey by simply scanning a QR code.

TELUS Agriculture is committed to creating a safer, more sustainable food system by connecting everyone in the food value chain. Learn more about our integrated solutions for

agribusiness

and food, beverage and consumer goods companies

.

Help protect the environment

Better digital policies will support our collective journey to net-zero.

Get informed